Beyond the immediate concerns of battery project developers (grid connection, revenue stack, finance etc), another key issue looms: the batteries’ future status (and value) as “waste”.

The Waste Batteries and Accumulators Regulations 2009 are aimed at battery “producers” and impose recycling obligations on battery manufacturers/sellers.

A “producer” is defined as “any person in the UK who, irrespective of the method used, places batteries, including those already in appliances or vehicles, on the UK market for the first time, on a professional basis“. We are seeing that the “producer” is the EPC Contractor as they are bringing the batteries into the UK market.

Producer obligations

Broadly speaking, producers must provide a scheme under which they accept to retrieve waste industrial batteries provided to end-users. This must be free of charge to the end-user and within a reasonable time following request by the end-user. The producer must also publish details of how an end-user can use the scheme.

These obligations only come into effect in certain circumstances, when requested by an end-user, and in the same year that a producer places batteries on the market.

Waste batteries

A “waste battery” means any battery which is waste within the meaning of the 2006 Battery Directive. The definition of waste is broad and includes other substances and objects rather than just batteries – so it needs to be properly considered in the context of a battery. The most relevant category of waste in respect of batteries would be “unusable parts”.

“Unusable” in its literal interpretation would be batteries which have been exhausted and have no further use.

Once the maximum cycle count of the batteries has been reached, there is still use for the batteries in a secondary market. If this is the case, then the batteries may be considered as “used” but not “unusable” and a producer would not be under an obligation to take them back.

Producer responsibilities

Based on the regulations, there are three distinct scenarios in which producers have a responsibility to collect batteries.

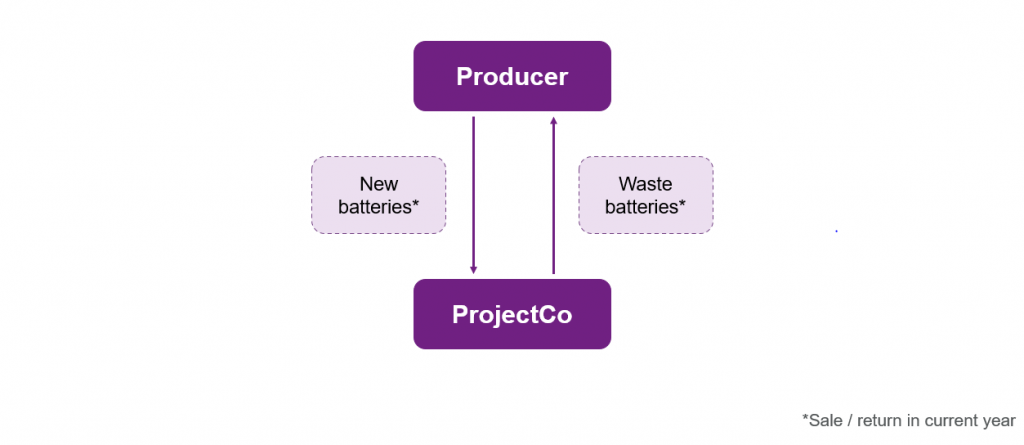

Scenario 1

The producer must take back waste batteries free of charge from its customer where such customer is supplied with new industrial batteries in the same calendar year.

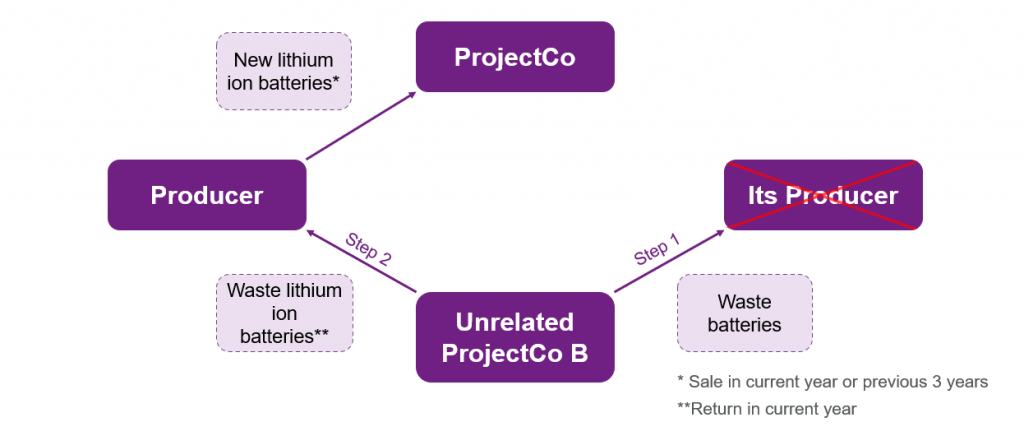

Scenario 2

The producer must take back third party waste batteries free of charge where:

- the third party end-user cannot return their waste batteries to their relevant producer; and

- their waste batteries are the same chemistry type as the batteries which a producer sold on the UK market in that or the previous three calendar years.

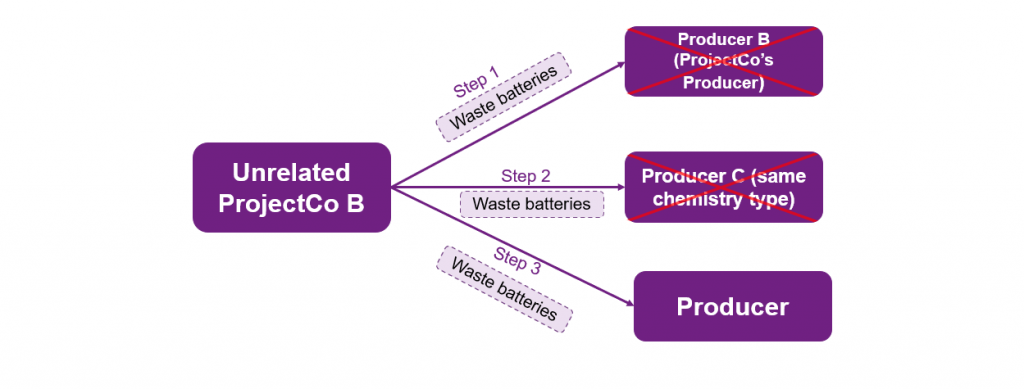

Scenario 3

The producer must take back waste industrial batteries free of charge from an end-user, where the end-user cannot return the batteries to another producer under scenarios 1 and 2 above. This is considered a catch-all to ensure that all waste batteries are collected.

It is clear that there is an unknown element of risk to which producers are exposed through having to accept the waste batteries from third parties.

The Regulations state that battery producers can agree to make alternative arrangements to finance the net costs of the collection, treatment and recycling which differ from the arrangements provided for under the Regulations. This means that any producer could in its battery supply arrangements agree to share these costs, or alternatively push them on to developers.

Depending on your side of the fence – developer or EPC contractor – you may wish a contract to remain silent, or expressly agree to share costs.

Further obligations

There are various other obligations including registration, record keeping, reporting requirements and ensuring that any batteries taken back are delivered to and accepted by an approved battery treatment operator for treatment and recycling, or an approved battery exporter for export for treatment and recycling outside the UK.

Battery project developers as “producer”?

We anticipate that over time, as the solar market did with modules, developers will become more comfortable in establishing themselves as producer – entering into BESS supply contracts directly with the manufacturer, which means that it is the developer placing the batteries on the market.

Whilst this could be seen as daunting, in our view, it does not need to be. Solar PV has comparative obligations under the Waste Electrical and Electronic Equipment Regulations. There is a similar definition of “producer”, take-back obligations, registration and reporting requirements as well as the process for recycling these components. Developers have managed to get comfortable with obligations regarding solar PV, so we think that it is reasonable to say that developers could also get comfortable with comparative obligations for battery recycling.

Our next blog post will look at the potential second-life application of batteries and how battery project developers can capitalise on this emerging market.